Capabilities

Virtual Design & Construction (VDC)

At DiGesare Mechanical, our Virtual Design and Construction (VDC) department is a cornerstone of our commitment to precision, efficiency, and innovation. Using advanced technologies—including 3D laser scanning and Autodesk Revit—we transform real-world conditions into intelligent, data-rich models that drive smarter project planning and execution.

Our team leverages 3D laser scanning to capture highly accurate existing conditions, allowing us to develop precise as-built models and reduce guesswork in complex renovations and retrofits. These scans are seamlessly integrated into Revit, where our designers and coordinators build fully detailed BIM models that support coordination, clash detection, and prefabrication.

From fabrication drawings to coordinated multi-trade models, our VDC process ensures constructability, code compliance, and seamless field installation. By identifying conflicts early and enabling off-site prefabrication, we help minimize rework, reduce timelines, and control costs.

Whether for new construction or occupied retrofits, DiGesare Mechanical’s VDC capabilities enhance collaboration, improve accuracy, and deliver mechanical systems that are built right—before we even reach the jobsite.

PREFABRICATION

DiGesare Mechanical’s in-house prefabrication shop enhances project efficiency, safety, and quality by assembling piping and plumbing systems off-site in a controlled environment. This process accelerates installation, reduces on-site labor, and ensures consistent, code-compliant results.

Using coordinated BIM models from our VDC team, we fabricate mechanical piping, plumbing assemblies, pump skids, and mechanical room components with precision. Prefabrication allows us to minimize jobsite disruption, reduce material waste, and improve overall project delivery—especially on complex or schedule-driven jobs.

Our prefabrication capabilities are a core part of how we deliver smarter, faster, and more reliable mechanical solutions.

PROJECT MANAGEMENT

DiGesare Mechanical delivers projects with precision and reliability through strong, experienced project management. Our team oversees every phase—from preconstruction to closeout—ensuring clear communication, tight coordination, and on-time delivery.

We manage schedules, subcontractors, and procurement while working closely with clients and partners to anticipate challenges and keep projects on track. Backed by our VDC, prefabrication, and field teams, we bring the leadership and technical expertise needed to execute complex mechanical systems with confidence.

Design-Build

DiGesare Mechanical offers streamlined design-build services that integrate design, budgeting, and construction under one team for improved speed, coordination, and cost control. Our in-house experts design efficient, code-compliant HVAC and plumbing systems, with support from our VDC and prefabrication teams to ensure smooth execution and faster installation.

When needed, we collaborate with trusted outside engineering partners to meet project requirements and deliver the best possible solutions. DiGesare’s design-build approach ensures flexible, reliable, and cost-effective mechanical system delivery from start to finish.

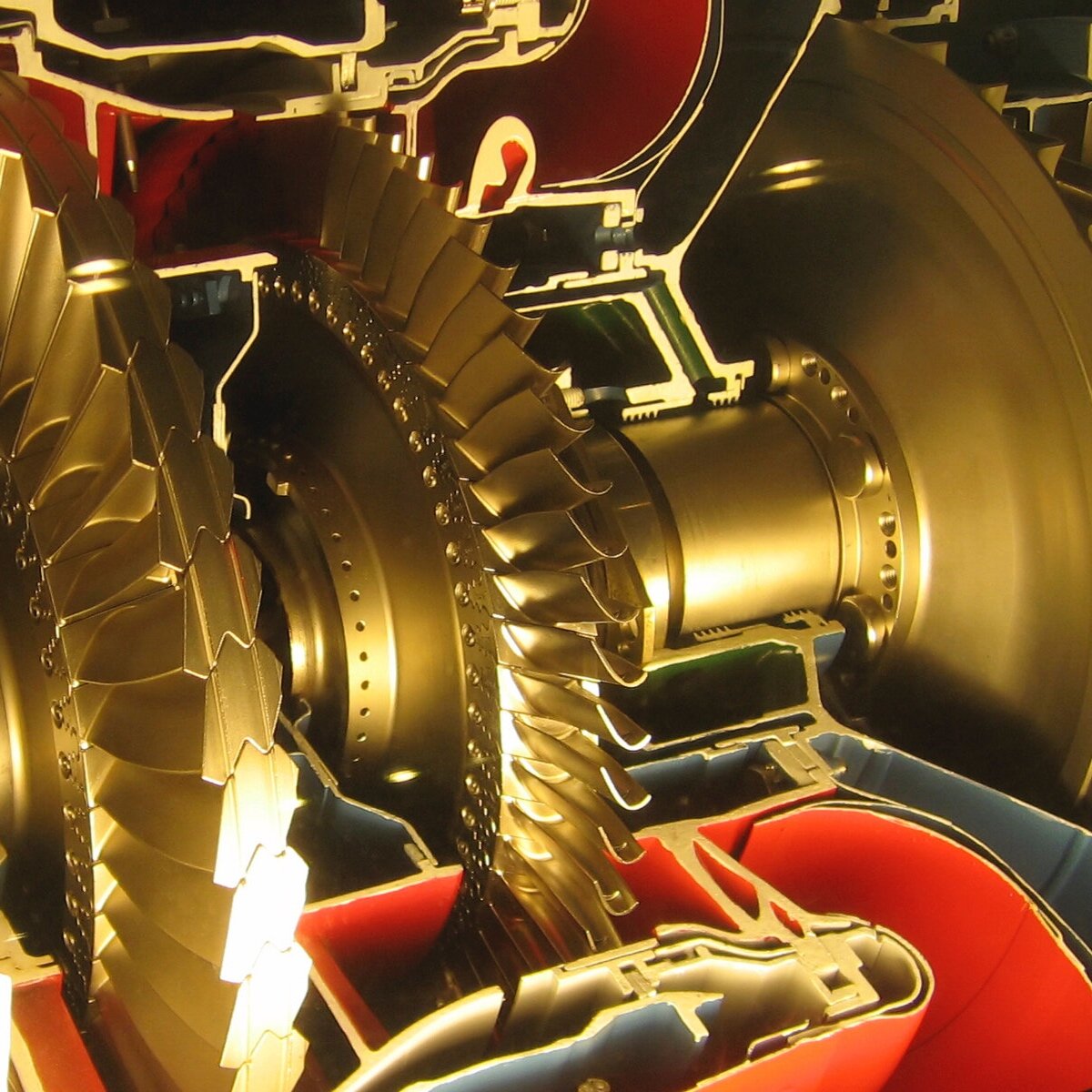

HVAC

We are proud to be the leading heating, ventilation and air conditioning contractor in the region. We perform work in virtually every market segment and project size. From air conditioning tenant improvements to high technology plants, high rise buildings to medical research facilities our experience is unmatched.

Our staff of trained professionals and field crews work closely to design, construct and install every type of sheet metal and piping imaginable for commercial, industrial, medical and manufacturing clients, big and small.

The HVAC industry is at the forefront of building comfort, energy management, safety, air quality and industrial processes. For many years DMI has proven its leadership to such clients as AT&T, KeyCorp, Albany International Felt Skidmore College and many others. Our reputation is based on quality and cost competitive installations and we are dedicated to that tradition.

PLUMBING/PIPING

DiGesare Mechanical was built on a solid foundation: plumbing and piping. Clearly the dominant element of mechanical systems of that era, plumbing and piping are equally dynamic today. From sanitary and domestic water applications to process piping and chilled water systems, “piping” is an integral part of both mechanical systems and DiGesare Mechanical.

Our piping crews carry an extensive service background, providing boilers, chillers, cooling towers, and refrigeration systems to complement the sheet metal installation.

For more than five decades DiGesare has engineered, installed and maintained piping systems of every size and complexity. Our project experience is broad including hotels, office buildings, biotech laboratories, industrial plants, manufacturing facilities, hospitals and institutional buildings. From our fleet of service plumbing trucks to our crews for major projects, piping is our tradition. We are proud to have performed for the best: General Electric Global Research Center, Union College, Ellis Hospital, Albany Medical Center, Playtex, Ayesrst Laboratories and many others.

Employing as many as 150 piping craftsmen is only part of the story. DMI prides itself on its commitment to engineering focus, innovation and prefabrication in the installation, upgrades and maintenance of piping and plumbing systems. When our team is involved clients can be sure of proper applications, quality and cost effectiveness.